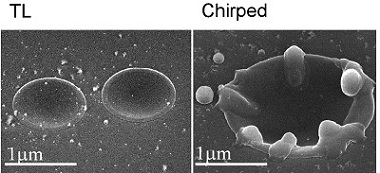

Effect of phase modulation on the morphology of micromachined features obtained on Si (100) wafer (scale bar = 1 mm). Images shown here are obtained with TL pulses (35fs) and highly chirped pulses (60,000fs2, equivalent to 1ps). Other conditions including power and focus are the same for both experiments. J. Appl. Phys. 106, 123101 (2009)

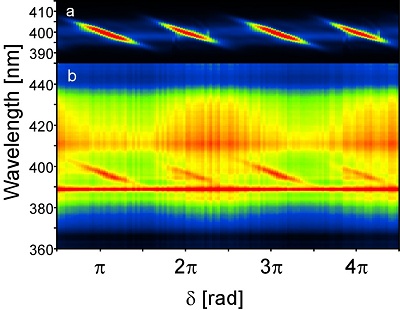

Si-LIBS and SSHG spectra obtained by applying sinusoidal modulation are plotted as 3D maps. Panel (a) shows a typical MIIPS trace obtained with a SHG crystal, and panel (b) shows all the emission components observed under micromachining conditions, including the broad plasma, the SSHG features which are similar to those in panel (a) and the Si atomic emission. J. Appl. Phys. 106, 123101 (2009)

Ultrafast Machining and Processing

Pulsed nanosecond lasers have already proven to be a commercially viable technology used to machine a variety of materials (steel, biological tissue, diamond). However, femtosecond laser pulses offer new set of useful properties and have yet to fully reach their potential. The short exposure and ultra-high fields of femtosecond laser pulses create the possibility of ablating without melting (machining without heat). This allows greater precision and virtually no damage in the machining process.

The focus of our group is on understanding and improving the complex, femtosecond machining process. Much of this work focuses on manipulating the temporal profile of the pulse, and monitoring the effect on ablation. Monitoring involves in-situ collection of real-time spectroscopic data as well as the eventual inspection of the machined area.